Biomass Gasification system is consisted by five parts which are the construction part, the gasification unit, the gas tank or gas container, the pipeline and the indoor facilities or IC engine.

1) Construction part

The construction part includes the yard for the plant which is 50×50 m2, within the yard, a house which size is 17m in length, 8m in wide and 4.5m in high is needed for installation of the gasification unit, also within the yard, a gas tank is to be installed and the gas tank should be 25m away from either the residential houses or the constructions within the yard. A storehouse which size is not fixed for depositing biomass fuel is also needed. An enclosing wall is needed for the yard. In the case of power generation, an additional house is needed for the IC engine; the size depends on the requirement of the IC engine.

2) Gasification unit

The gasification units includes a screw conveyer, a gasifier, two cyclones, a scrubber, a water separator, a biomass filter, a roots blower, a water seal, a control panel, two pumps and the necessary pipelines as well as the valves.

Gasifier

The gasifier is a downdraft fixed bed gasifier, it enables a high temperature in the reaction zone, the grate locates on bottom and adopts an enhanced air distributing system in order to ensure a complete reaction, therefore it can suit widely to various types of biomass as fuel including residues from lumber mill, branch of trees and agricultural refuses.

The residue of gasification is mainly plant ash which can be used as fertilizer for the farm field.

Cyclone separator

The separator is improved on the basis of the tangency-flow cyclone separator, and built up inside a stuffing layer in it for improving of the efficiency of dust removing. So the separator is named a stuffed cyclone separator. In the operating process, those impurities being removed by the stuff and dusts drop down to the dust cabin, and then take them out regularly, and the stuffing layer could be cleaned or replaced as well. In the gas conditioning system, two of separators in parallel connection are installed.

Scrubber

The scrubber catches and gathers the dust and tar content with water atomizing way in the directions of obverse or reverse according to different condition, and the scrubbing water which amount, according to the capacity of the system, is around 400kg is circulated in the scrubber before it becomes dirty enough and is drained out. In general, it should be changed at an interval of one week. The scrubber was also designed as the heat exchanger, which can be cooled with the water in a water tank, and so the investment of the cooling equipment is diminished.

The used scrubbing water is discharged into a pond of 20 m3 in volume for condensing, and then the condensed water in which the most parts are tar and ash content will be mixed with coal or other material for combustion. This will not pollute the environment.

Biomass filter

This filter consists of single filtering layer in horizontal position using sawdust and chopping pieces in different size, which can also be taken out to be the feedstock of gasifier after drying in the open air.

Roots blower

| Item | unit | value |

| Flow rate | m3/min | 1.1~16.5 |

| Total pressure | mmH2O | 2000 |

| RPM | r/min | 960~1440 |

| Power | kW | 1.2~11 |

3) Gas tank or gas container

There are two kinds od gas tank, one is traditional wet gas tank, as see in Fig 2, in cold area where there is the freezing problem, the general solution to prevent freezing is to put the water container underground and construct a greenhouse outside, and put inside the water some salt to lower the freezing temperature, the other one is dry gas tank in which there is the flexible rubber membrane, as see in Fig 3, the rubber membrane works like a bellows, this kind of gas tank eliminates the problem of freezing and will save a lot of cost for maintenance, the cost for dry gas tank is similar to that of a wet gas tank with anti-freezing accessories. Of course, without considering of freezing problem, wet gas tank is economic and will cost only half of the one which contains anti-freezing accessories. In any case, the pressure of the gas tank is around 400 mm H2O column.

In case for power generation, the volume of the gas tank is 200Nm3, which is used for stabilizing the producer gas composition and enable the IC engine to operate steadily, the pressure of the gas tank will depend on the requirement of IC engine.

1water container 2 inlet 3 floating cover 4 guide track 5 overflow pipe 6 outlet Fig 2 Wet gas tank

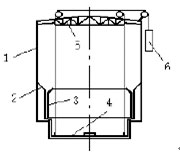

1 External cylinder 2 Flexible rubber membrane 3 floating cylinder block Fig 3 Dry gas tank 4 piston 5 roof 6 balancing

4) Pipelines

The pipeline is underground installation, the depth of the pipe installation depends on the earth freezing layer thickness. Along the pipe, there is a gradient of 0.005, depending on the length of the pipe and the topography, there are certain amount of water container to collect the condensed water in the gas. The material of the pipe is polyethylene and the life span of the pipe is 50 years.

5) Indoor facilities

The indoor facilities consist of a cooking stove with biomass gasification producer gas as fuel, a gas meter, two valves, several meters of iron pipe and at most, one meter of flexible plastic tube. The power of the cooking stove is 3kW at an efficiency of around 50%; the capacity of the gas meter is 6Nm3/h. The gas pressure before the cooking stove is around 100mm H2O column.

6) IC engine

IC engine will be selected by user.

IV. Operation & Administration

In general case, two operators are needed for the operation of the plant; the administration of the plant is done by the village manager. The plant will collect biomass feedstock from its village and other villages in the vicinity. According to experience, 5Nm3 producer gas is needed for every household per day, which means 2.5kg biomass is needed for one household per day, according to this calculation, the manager will know the total amount of feedstock needed. The plant will collect the charge for gas consumption from the households which use the producer gas.

V. Price of Biomass Gasification for Power System (Exclude IC engine, gas tank, pipeline)

US$

| Capacity of power generation | 15kWe* | 30kWe* | 50kWe | 100kWe | 200kWe | 300kWe* |

| FOB Price* | 50,000 | 60,000 | 75,000 | 80,000 | 90,000 | 105,000 |

*The price excludes the cost for installation, domestic and international traveling expense. *Only available for using wood as feedstock. *The valid duration for this quotation is 60 days.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us! |

|

| *Your Name: | |

| Phone: | |

| *E-mail: | |

| Regrading: | |

| How did you find us? | |

| *Message: | |